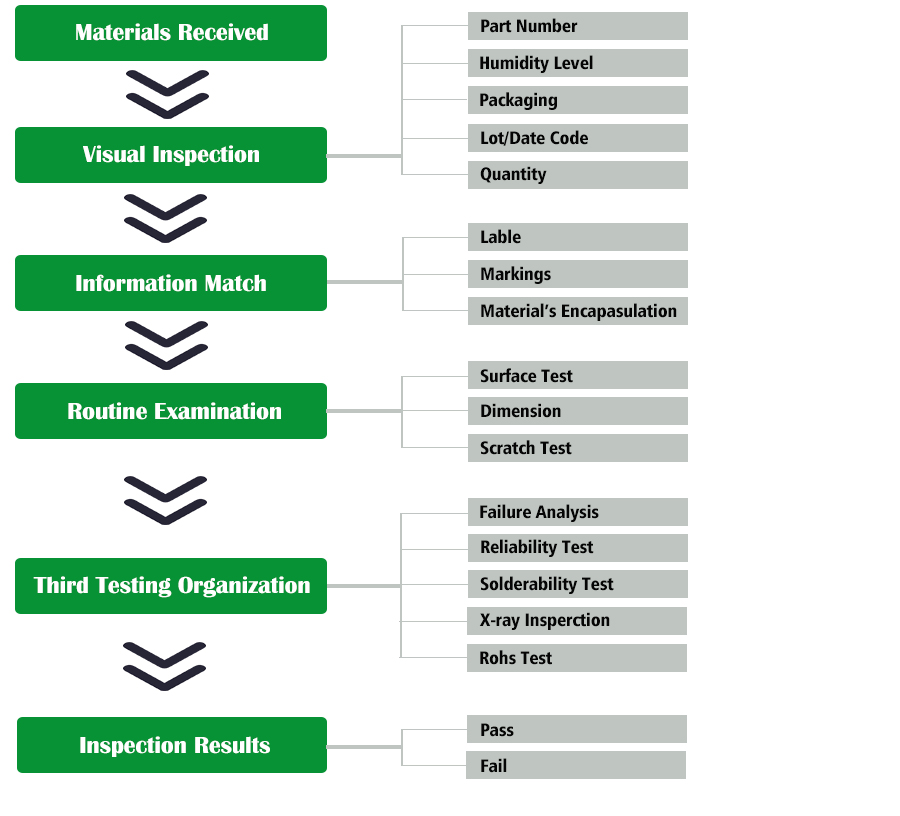

SUNTOP believes that regular supply channels are the basis, and we always insist on testing each batch of products in and out of the warehouse. All products must be tested in accordance with the company's procedures for entering and exiting the warehouse. At the same time, we have an authoritative third-party inspection agency as technical support, to help us complete the sample inspection of outbound goods.

Quality Control Database Management

Strict quality control process is an effective means to ensure that customers use "zero defect" products, and powerful IT systems, real-time quality control database management is the most powerful backing. Details of all import and export products will be uploaded to our quality control database for archiving, including:

● Quality control sheet, detailed record of goods storage information;

● Sample placement files;

● Photo files of purchase details;

● File photos of delivery details;

● Documentation of unaccepted product information, the submission of supplier audit/classification management system process;

● Quality inspection analysis/report files;

● Original factory contact information file.

Storage / Packaging / Transportation Standards

Electronic components are sensitive items that have strict requirements for the storage/packaging/transportation environment. We strictly adhere to the original environmental standards for all levels of materials, from electrostatic protection, humidity control to thermostatic control, we are committed to the original requirements for the corresponding items to ensure the quality of the goods. "Zero defects" goods delivered to the customer.